You may know the Fluid Bed, now meet the Ventura®

Maximize energy savings with Ventilex Ventura®

Revolutionize sand drying with Ventilex Ventura®! Our cutting-edge Ventura® system delivers up to 35% energy savings while optimizing your drying process. Unlike traditional fluid bed dryers, the Ventura® utilizes an advanced two-stage drying system that integrates into a single fluid-bed setup. By recirculating process air in the first stage with a minimal refresh rate, it achieves high dew points, enabling heat recovery for the second stage. This results in up to 35 % lower energy consumption, consistent product temperature at 40°C, and enhanced sustainability.

The future of sand drying: Ventilex Ventura®

Drying sand for mortar production is one of the most energy-intensive processes in industrial operations. With increasing pressure to reduce energy consumption and CO₂ emissions, the Ventilex Ventura offers an innovative, sustainable solution. This advanced two-stage dryer integrates into a single fluid-bed system, delivering exceptional energy efficiency and consistent results.

Why choose the Ventilex Ventura ?

- Reduce energy consumption by up to 35% compared to traditional systems.

- Maximize energy efficiency: Process air is recirculated in the first stage with a minimal refresh rate, achieving high dew points and enabling heat recovery for the second stage.

- Consistent product temperature: Products exit the system at a stable 40°C, independent of ambient conditions.

- Proven reliability: In operation since 2007, Ventura systems deliver consistent results worldwide.

Recent advancements, including an advanced digital twin model, ensure the Ventura adapts quickly to changing site conditions without sacrificing energy efficiency.

More and more companies are turning to the Ventilex Ventura to reduce energy consumption and minimize their environmental impact.

Get in touch

By working with our engineers, partners and customers, we have developed 4 focus areas for energy savings/efficiency:

- 1: Stock pile management: smart management of raw material stockpiles, avoiding unnecessary moisture accumulation, and thus avoiding unnecessarily high drying energy consumption.

Impact: 5-25% energy savings. Time to develop: short, immediately possible.

- 2: Optimizing existing systems: even without making any changes to existing dryer equipment, the practice shows that a lot can be done to save energy, by optimizing operational setting, smart equipment management and higher awareness of operating personnel.

Impact: 5-10% energy savings. Time to develop: short, immediately possible.

- 3: Upgrading existing equipment: upgrading existing equipment with additional energy saving functionality such as recirculation systems, heat pumps systems, twin coil technology, evaporative cooling technology, etc.

Impact: 10-20% energy savings. Time to develop: medium, 6-12 months.

- 4: Innovating new equipment: developing fundamentally new equipment with high energy savings. Ventilex’ Ventura® system innovation was released in [2006], and a second generation Ventura® is being developed.

Impact: 30-40% energy savings. Time to develop: medium-long, 12+ months.

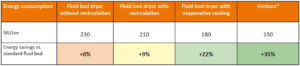

The focus areas mentioned can be summarized in the following table:

Note: based on sand with 5% moisture and 15 °C infeed condition, dried to 0.2% moisture content and < 45 °C exit temperature.

Thus, although innovation of high energy saving dryers is an absolute necessity, high energy savings can already be achieved with short term action in stock pile management, smarter usage of equipment and targeted upgrades of existing equipment. Below we will describe each energy saving focus area in more detail.

1 Stock pile management

The first and the easiest way to save energy is achieved by natural dewatering. This is done by good stock pile management. Depending on the initial moisture content of the product, moisture reductions of 1-3% are achieved, which result in an overall energy saving of 5-25%.

Why stock pile management:

- Easy system to remove water without energy costs.

- Constant humidity in the sand/gravel batch, no (or less) wet spots anymore.

- Higher capacity of dryer, due to the inlet humidity being constant.

How to handle the stock pile management:

- Roof above storage of wet sand, saves a significant amount of energy.

- Natural dewatering for at least 24 hours.

- Don’t use the lower part (1 meter) of the sand. This always contains too much water.

2 Optimizing existing systems

Small savings on energy loss are achieved by optimal operation of the system. Ventilex proposals for the existing units are:

- Optimizing software and controls

- End-moisture control

- Datalogging & remote consulting for optimal operation of the system

- Training of operators

Impact: 5-10% energy savings. Time to develop: short, immediately possible

3 Upgrading existing units

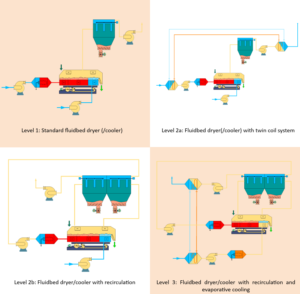

Most existing units can be upgraded to a more energy-efficient system, depending on the layout and execution of this system. Ventilex delivers systems in 4 energy levels. The fourth level, which we called the system ‘Ventura’, is described in the following chapter. The three remaining levels are described below:

- Level 1: Standard fluid bed dryer (/cooler) without recirculation of the cooling air.

- Level 2a: Fluid bed dryer (/cooler) with twin coil system.

- Level 2b: Fluid bed dryer/cooler with recirculation of the cooling exhaust air.

- Level 3: Fluid bed dryer/cooler with recirculation of the cooling exhaust air and evaporative cooling of the remaining moisture in the cooling zone. The cooling zone is a low-temperature drying zone, where the cooling air is heated by means of a twin coil system and, if necessary, the air temperature is controlled by means of a small burner.

Impact: 10-20% energy savings. Time to develop: medium, 6-12 months

4 Innovative new equipment

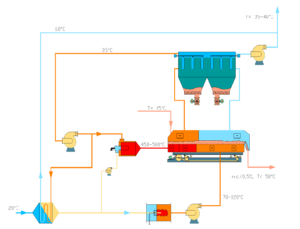

For a system with a higher level of energy savings, an upgrade is not possible. The unit has to be replaced for a so called ‘Ventura®’ dryer. This unit has a small high-temperature and humidity zone within. With the latent heat in the exhaust gasses of the first zone, the drying air of the second zone is heated. The second zone is a low temperature drying zone where, if necessary, the air temperature is controlled by means of a small burner.

Impact: 30-40% energy savings. Time to develop: medium-long, 12+ months

Ventilex Ventura®

Final remarks

Inventions and sustainable energy

In addition tot the options above, Ventilex also develops other types of energy saving and renewable energy sources for its customers. Some examples:

- Heat pumps

- Electrical heating

- Combination with a CHP system

- Moisture reduction by vacuum filter press

The options above can also be discussed.