Safe and healthy steam sterilization of spices & herbs

Spices and herbs bring a world of flavors, aromas and colors to our dining tables.

Spices and herbs are sourced worldwide and they may be heavily contaminated from the soil where they were grown and harvested.

If left untreated, these products can provide perfect conditions for continued growth of the microbes which can lead to spoilage and consumer health issues.

Even after local processing microbes often remain, due to inadequate treatments and processing at low temperatures.

The potential for pathogens like salmonella, yeasts, molds, Enterobacteriaceae and spore formers to get into the food supply has resulted in the trend towards more stringent Good Agricultural Practices and regulations.

There are many methods to decontaminate natural products, such as ethylene oxide and irradiation but most have been or will soon be restricted due to their potential health risks and adverse consumer acceptance.

Aside from health risks, food technological aspects such as the inactivation of enzymes, e.g. amylase and lipase, cannot be solved by irradiation or ethylene oxide treatment.

These enzymes have been shown to cause a breakdown of fat and starch components in sauces, salads and many ready-made meals.

Get in touch

Ventilex safe continuous steam sterilization

Modern, hygienic and chemical free elimination of bacteria

As a result, many of the world’s largest spice processing companies have selected the Ventilex Continuous Steam Sterilizer.

Steam is ideal as it is non-toxic, inexpensive and can be produced in an unlimited supply. It is a natural ‘organic’ process that does not leave behind any chemical residue or create toxins. Steam sterilization systems are the most effective ‘natural’ method for reducing or eliminating bacteria, pathogens, and other food-borne causes of sickness. Effective steam treatment will eliminate listeria, salmonella, E. Coli, and a variety of other bacteria and pathogens.

With the Ventilex system, you get a continuous ‘inflow’ of high pressure steam that results in the elimination of undesired microorganisms while causing the minimum harm to the organoleptic characteristics (flavor, color, texture or taste) of spices, herbs and nuts.

Steam sterilization offers many other advantages. It is the fastest possible way of heating product to an exact preset temperature. Condensation on the product provides the water activity required for effective sterilization while protecting the product against overheating and burning. The steam condensed on the product also enables flash cooling of the product when it leaves the sterilizer and is returned to pretreatment specifications in an integrated Ventilex Dryer / Cooler system.

The Ventilex Sterilizer treats powders as well as whole spices, which is a unique feature. From chili powders to whole and ground pepper, paprika, garlic, cloves etc., and a variety of herbs, seeds, and other spices. We can do leafy spices without harm to the leaf due to our gentle shaking action – there is no screw conveyor that can damage the product.

Steam sterilization benefits

- Natural and renewable process that utilizes steam and is accepted worldwide as safe and wholesome

- Continuous decontamination of bacteria and pathogens

- High-temperature, short-time processing (htst) which protects the taste, texture, and color of the product and a minimal loss of volatile oil

- Very gentle for leavy products

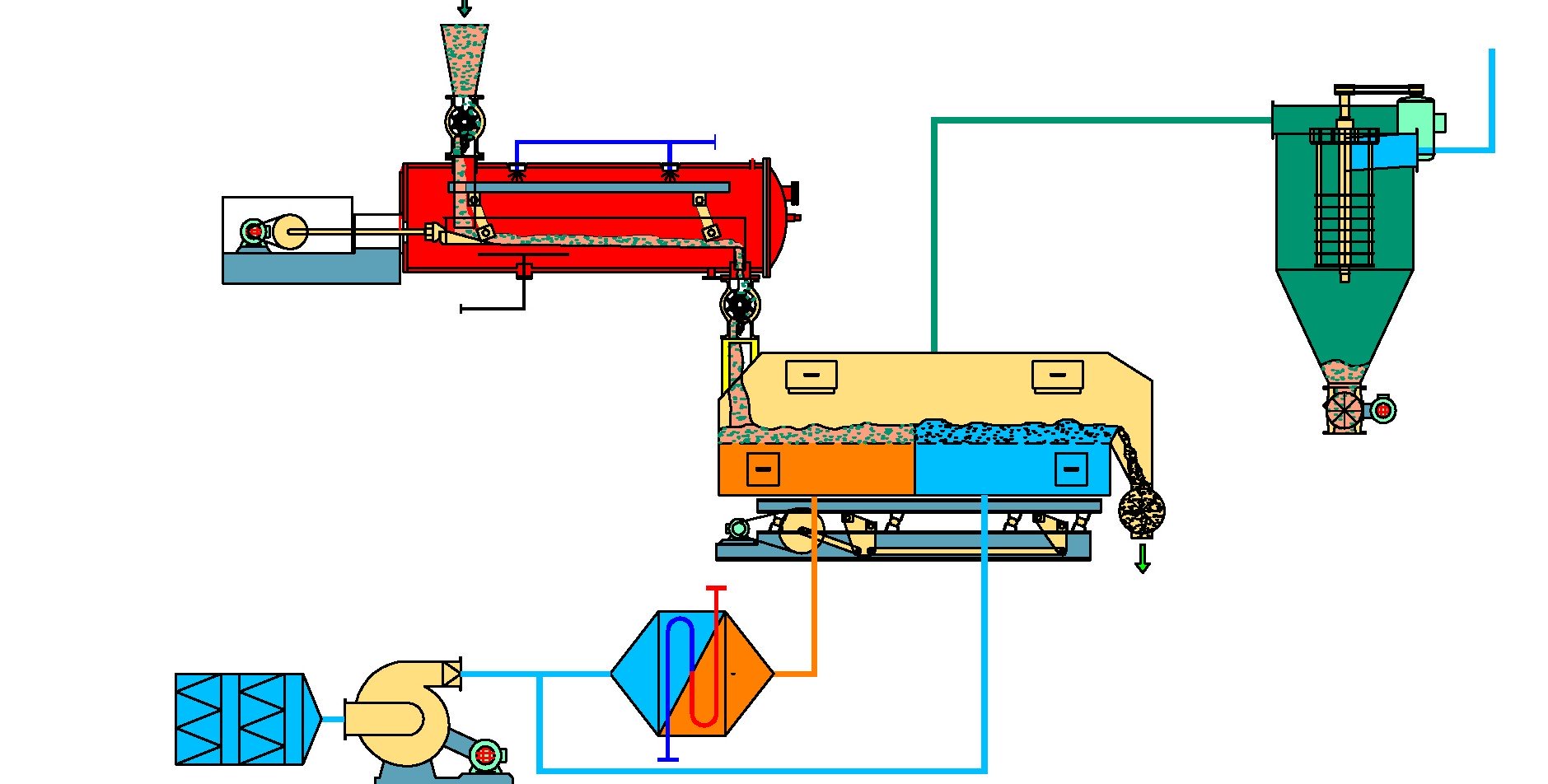

How does Ventilex steam decontamination work?

Ventilex continuous steam sterilization systems are designed for high-temperature, short-time (HTST) decontamination. Steam is the fastest possible way of heating product to an exact preset temperature.

The HTST process exposes materials that are considered contaminated to high temperature steam for just a short time. The material is then dried and cooled. This is a simple idea, but is one of the most practical and effective methods for treating products in this industry.

Steam-pressurized chamber

The process works by feeding and discharging the product through a self-cleaning pressure rotary valve that isolates an autoclave from the ambient room. Inside this autoclave, a shaking table transports product through a steam-pressurized chamber at a specific speed and creates a thin layer of product. Condensation builds on the product surface and this imparts high energy into the surface of the product. This kills unwanted bacteria and pathogens.

Tightly controlled

The time, pressure and steam temperature within the chamber is tightly controlled – just the minimum that is required to achieve the desired kill is what is applied. Afterwards in the dryer the temperature is tightly controlled so that the product is returned to a precise moisture level. In this way, the final moisture content can be specified and controlled to maximize yield.

Meeting the client’s specifications

We typically work with a ‘Process Authority’ or the client’s microbiologist who performs the microbiological testing and sets the process parameters to be validated for regulatory compliance.

Our role is to supply equipment meeting these specifications.

However, we offer a testing service to process samples inoculated with surrogate pathogens for process parameter development.

Repeatability and validation

We understand how critical temperature, treatment time, and pressure are when decontaminating spices and herbs. All three of these parameters can be set for individual products and each pathogen to be eliminated. Repeatability is required to validate a system and ensure effective decontamination, so our systems are designed with advanced PLC controls to provide this. The operators simply choose the right recipe from a menu and all process parameters are controlled and measured for traceability. and creates a thin layer of product. Condensation builds on the product surface and this imparts high energy into the surface of the product. This kills unwanted bacteria and pathogens.

Standard sterilizer capacities:

- 0.9 m3/hr.

- 2.5 m3/hr.

- 4.5 m3/hr.

Ventilex steam sterilizer features

- Minimal operator intervention – automated controls; operator only needs to select the right recipe, setpoints are always the same

- Data logging and PLC instrumentation, which makes processes repeatable and verifiable. Stores all critical data permanently

- Automatic sanitary Clean-in-Place (CIP) design – fastest system to clean on the market today

- Recipe based (for processing multiple products) – validated process

- Hygienic design, high quality finish

- Product is decontaminated, dried and cooled

- Shortest duration of steam of any commercial system in use today – product still ‘natural’

- Low energy consumption and low maintenance costs

- 5 log kills are typical

- Deactivation of enzymes

- Minimal loss of flavor, color and volatile oil