Optimizing gelatin dryer efficiency

The global gelatin market continues to grow, and companies are looking for efficient manufacturing processes. The improvement of the drying stage, in particular, can lead to interesting enhancements. At present, 50-60% of global gelatin is dried with a Ventilex DryGenic gelatin dryer. Read how we optimize the gelatin manufacturing process by increasing the efficiency of the gelatin dryer.

Gelatin origins and market size

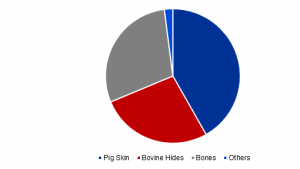

Let’s start with some background information. Gelatin is derived from collagen, a bodily protein substance. The three main sources of gelatin are cattle bones, pigskins and bovine hides. Porcine gelatin is a hydrolyzed form of pork collagen. Bovine gelatin comes from cattle. At present, pigskin is used most often, closely followed by bovine hide. However, cultural and religious objections to the use of bovine, and particularly porcine gelatin, have led to an emergence of the use of fish by-products.

Global gelatin market size in 2017, source: adroit market research

The rise of the gelatin market

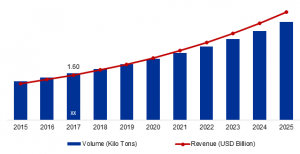

Gelatin has been used for centuries, but in recent years, the global gelatin market has grown significantly. Higher age and increased health-awareness spurred the demand for functional and nutraceutical foods. This, in turn, has led to a rise in the production of food-grade gelatin, collagen peptide and sub protein. After all, gelatin is not just high in protein and low in fat. It also has excellent stabilizing, binding, and emulsifying properties, enabling its use in a wide variety of food products.

In addition, gelatin possesses properties like wound-healing, biodegradability, and a high absorption rate, driving the demand for medical and pharmaceutical-grade gelatin. Its thickening and gelling properties make it appealing for use in the personal care market.

As can be seen in the image below, the rise in the production of food-grade, medical and pharmaceutical-grade gelatin, shows no signs of stopping:

Global gelatin market size, source: adroit market research

However, with the growth of the gelatin market comes the challenge of optimizing the gelatin manufacturing process. The improvement of the drying stage, in particular, can lead to interesting optimizations.

The gelatin manufacturing process

Pretreatment

When the raw materials come to the processing plant, they are first washed to remove debris. Hair is removed from the hides, and all materials are boiled to degrease them.

Gelatin hydrolysis

Next, the raw materials are hydrolyzed using acid or alkali. Acid treatment is predominantly used for pigskin and requires up to 2 days. The gelatin obtained in this way is called type-A gelatin. For the treatment of bovine hide, alkali is typically used. It takes several weeks to obtain this gelatin type B.

Gelatin hydrolysis can also be performed using enzymes, which requires less time than alkali gelatin hydrolysis. It is also said to result in more yield and better-quality gelatin.

Gelatin extraction process

During the gelatin hydrolysis stage, the protein molecules are dissolved in hot water, giving diluted solutions of gelatin. The gelatin extraction process consists of four to five cycles of boiling the raw materials in water or acid solutions. Each time, approximately 4% gelatin solution is extracted by drawing off the gelatin liquid. On a side note, the gelatin extraction process can be done using water or acid, but never alkali, as this results in gelatin degradation.

Gelatin filtration and evaporation

The next step in the gelatin manufacturing process is gelatin filtration: the liquid is pressed through filters to remove any bone, tissue, or skin that might still be present. Evaporators are then used to concentrate the substance. A sterilization process completes this step.

Get in touch

Gelatin drying

After filtration, concentration, and sterilization, the liquid will be dried until it contains about 88% gelatin and 12% water. At Ventilex, the drying process starts by cooling the gelatin in a chemetator unit. This unit consists of a horizontal heat transfer cylinder furnished with scraper blades, a high-pressure pump, and an extrusion head gelling section.

The removable heat transfer tube is made of carbon steel and has been hard-chrome plated on the inside. All other contact parts are made of stainless steel. When the gelatin cools down, it spreads out on a stainless-steel conveyor belt in the form of a noodle. Next, it is transported into the drying tunnel.

The drying tunnel

The Ventilex gelatin dryer is essentially a conveyor belt dryer. The gelatin is dried by blowing regular dry air over the surface of the noodle, forming a thin layer that prevents the sol-gel from re-liquifying when the air temperature is progressively increased.

Alternately, the dry air from the DryGenic gelatin dryer is passed in cross-flow through the gelatin layers, which are laid out on a perforated plate system. The gelatin-drying tunnel is divided into zones, each maintaining a different temperature. In the first zone, the supply air temperature is approximately 40°C, and in the last zone, the air is heated until 60°C, thus preventing gelatin degradation from occurring.

The tunnel is designed to achieve uniformity of air and water by state-of-the-art hot water injections and high-tech aerodynamics.

Gelatin grinding

The gelatin leaves the conveyor belt dryer in the form of a mat, which is broken into pieces of about 20 mm in length, called granulated gelatin, and stored in big bags. Alternatively, the granulated gelatin is transported to a fine grinder that turns it into gelatin powder, which is sieved, mixed, and packed.

This, then, is the gelatin manufacturing process commonly used in plants worldwide. So, what about the optimization of the drying efficiency we mentioned at the start of this article?

Becoming the world’s leading gelatin drying manufacturer

The Ventilex DryGenic dehumidification system dates back to the 1930s, when Dr. Binchowsky invented the method while working with refrigeration equipment, and later air conditioning machines. It was this organization, the Surface Combustion Company (SCC), that continued his work in 1950, when they were commissioned to help Atlantic Gelatin solve their drying issues. Considerable research was carried out and the gelatin drying process was successfully optimized.

Gelatin knowledge and experience were exchanged between the SCC and Imtech DryGenic. In 1961, the first gelatin dryer on the European continent was built at DGF Stoess & Co GmbH. A few years later, Nienburg Gelatin GmbH implemented a new concept that led to considerable money-saving and space reduction, not to mention a far better control of the gelatin drying process.

Imtech DryGenic kept their focus on the reduction of energy and operating costs, developing a process in 1975 which used waste heat of the vacuum evaporator and extracted part of the air volume from the gelatin dryer. In the early eighties, a hot water system was implemented and in 1995, higher moisture removal efficiency was achieved, resulting in additional space reductions, as well as decreased installation costs.

After that, additional adaptations led to a reduction of insulation requirements and subsequent maintenance work. A more hygienic dehumidification system was implemented and longer equipment life was achieved. In 2015, Ventilex initiated 1.5-year research and development program in concert with the University of Twente, the Netherlands. This collaboration resulted in an avalanche of information about the behavior of the gelatin drying properties, enabling us to carry out more process optimizations. Among these are:

- 40% energy reduction

- 15% carbon footprint reduction

- 5% down-time reduction

Incidentally, the knowledge gathered by Imtech DryGenic, and later Ventilex, is not only based on ‘standard gelatin’, but also on raw materials, such as fish, ossein, chrome-based hide and carrageenan.

Nowadays, 50-60% of the worldwide gelatin production is dried using Ventilex DryGenic equipment.

The most common gelatin drying issues

As described in the separate text block, Ventilex has been involved in gelatin drying techniques for almost a century. Due to our experience, we have grown to become a leading gelatin dryer manufacturer, delivering 50 to 60% of all gelatin drying equipment worldwide. Below, we will discuss three common gelatin drying issues and explain how Ventilex DryGenic provides solutions.

Gelatin degradation and crumbliness

On one hand, when gelatin is dried at overly high temperatures, gelatin degradation may occur, leading to quality loss. On the other, when gelatin is dried at temperatures that are too low, the gelatin may become brittle, affecting the application of the substance in functional and nutraceutical products, as well as other applications.

What is the optimal temperature? Which humidity levels should be maintained to avoid gelatin degradation? The answers aren’t straightforward, as gelatin types, concentration, and ambient humidity and temperature affect the drying process.

Therefore, smart equipment is required. Our DryGenic dehumidification system enables minute temperature and humidity control and adapts to daily and seasonal changes. Moreover, our gelatin dryer can be configured according to your specific site and product conditions. Hence, optimal temperatures and humidity levels can be established, leading to superior product quality.

Inefficient energy use

Another issue related to the gelatin manufacturing process is its ample energy use. All stages require substantial amounts of energy, and drying (and cooling!) of gelatin is no different.

Using waste heat and cheap coolants

Already in 1975, our engineers found ways to save energy by using waste heat of the evaporator, and by extracting part of the air volume of the gelatin dryer. Furthermore, our system uses relatively cheap coolants, like well water, river, and cooling tower water, to help chill the gelatin. Dew-point humidity can be as low as -7°. Due to these measures, operational costs are significantly reduced.

DrySol: an industrial desiccant dehumidifier

In addition to these technical enhancements, we base our dehumidifying system on the drying properties of a liquid hygroscopic solution, called DrySol. The lowest-energy desiccant dehumidifier on the market, moisture removal is directly related to the concentration and temperature of the gelatin solution. Moreover, this industrial desiccant dehumidifier is easily accessible and has low replacement costs.

Due to our collaboration with the University of Twente, the Netherlands, we have been able to reduce overall energy use by a whopping 40%. Additionally, our carbon footprint was reduced by 15% and equipment downtime went down by 5%.

Is gelatin safe?

A third gelatin drying issue we would like to mention has to do with food safety: Is gelatin safe in use? Apart from any discussions on diseases like BSE, our production processes are fully safe. First of all, DrySol is a non-toxic bactericidal solution, which, when sprayed into an air stream, effectively removes and kills up to 97% of all airborne bacteria, molds, fungi, and specific viruses. Furthermore, it is not poisoned by hydrocarbons and not affected by normal plant environments;

Secondly, our dehumidification system also eliminates the problem of “wet” cooling coils, which are known breeding grounds for bacteria and molds. At long term storage, this adds significantly to product quality. In short, discovering optimal temperature and humidity levels allows for superb gelatin quality, at lower energy costs and while maintaining food-grade, or pharmaceutical-grade quality.

Optimize your gelatin production process

Would you like to find out how our test engineers can help optimize your gelatin dryer? Then we welcome you to contact us. We can test your current product quality and optimize the drying process in our test center in Heerde, the Netherlands. Alternatively, we can visit your site to optimize your current drying process.

Questions? Contact us!

If you would like to learn more about the DryGenic gelatin dryer or have any questions about this article, we welcome you to contact us at any time!